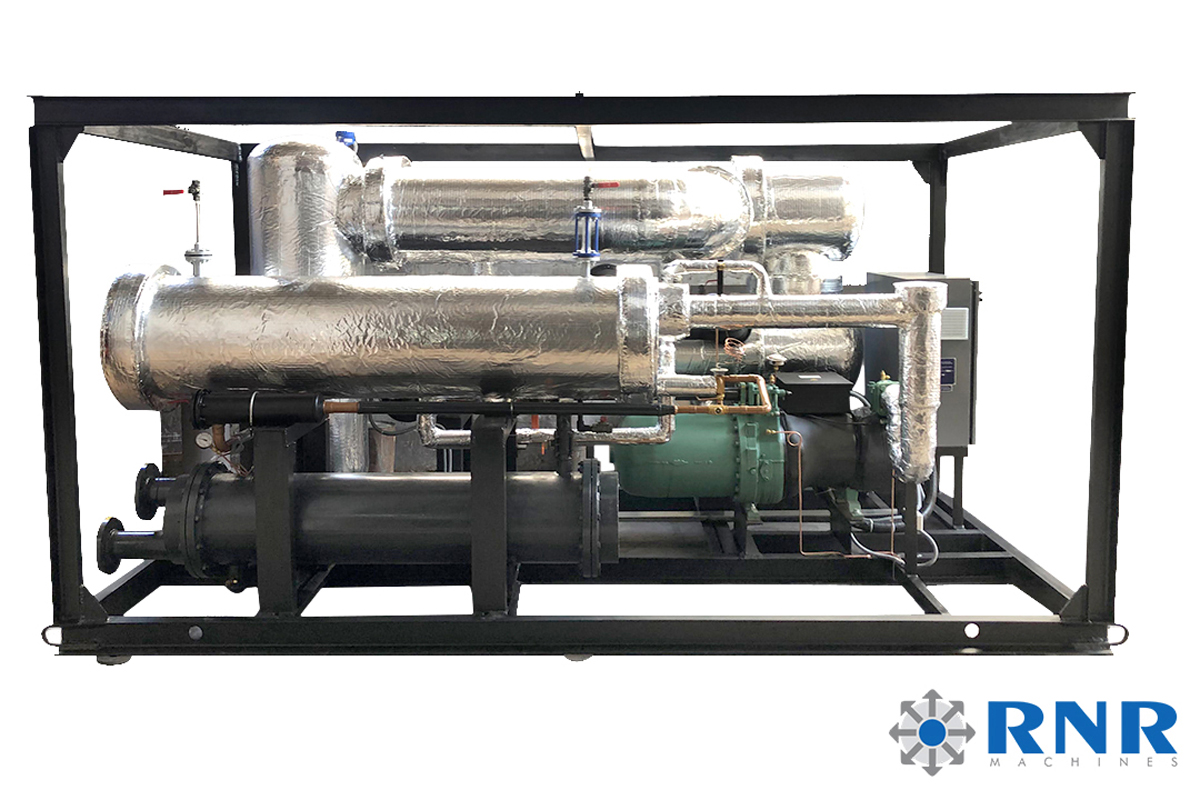

Thermal Mass / Fly Wheel Dryer

RNR/ Exal manufactures some of the largest Thermal Mass Air/Gas Dryers globally for Compressed Air / Gas. The Thermal Mass/ Fly Wheel dryer is a refrigerated dryer with an additional secondary thermal mass under circulation.

Compressed Air/Gas enters the dryer through a Gas to Gas heat exchanger. The incoming Gas/ Air is pre-cooled using the outgoing dry Gas/ Air. This economizer heat exchanger can enable a reduction in cooling heat-load 10- 40% or more depending on the working pressure and compressor discharge temperature etc.

The pre-cooled Gas / Air then is cooled using a thermal pass which is glycol or equivalent thermal mass which can store energy. In the process of cooling, the moisture in the Gas / Air condenses. The pressure dewpoint achieved is around 3oC (at pressure dewpoints less than 3oC moisture starts forming ice and can lead to heat exchanger failure even under high pressure.)

The cold thermal mass is circulated using a pump. The thermal mass itself is cooled in an evaporator by direct refrigerant expansion.

NOTE: By default the secondary thermal mass cooling circuit has additional pumping costs. In addition due to approach temperatures and inefficiencies of heat exchangers there is an additional power consumption. The double approach between Air/Gas to Thermal Mass and Thermal Mass to Refrigerant results in the refrigerant being operated at a lower evaporating temperature. The result is a reduction in compressor COP. The Thermal Mass/ Fly Wheel dryer will hence consume approximately 10-20% more power than an equivalent refrigerated dryer. Thermal Fly Wheel dryers might operate at negative evaporating temperatures based on the dewpoint needed. They are useful when additional connections are provided for usage with V.A.M. chillers. The refrigerant circuit provided in this dryer is then a stand-by circuit in case of issue with V.A.M. or screw/ centrifugal chillers.

RNR/ Exal thermal mass/fly wheel dryers can be designed for blowers and compressors. This includes working pressure as low as 0.5 Bar(g) and up to 70 Bar(g).

All our systems are designed based on proper heat load calculations coupled with simulation based evaluation of each heat exchanger to determine pressure drop and heat transfer area effectiveness. For the heat-load we take into account the Kg/Hour of Compressed Gas/ Air and Moisture entering the system. In addition, we consider the moisture quantity at the inlet of dryer based on compressor inter-stages, compressor suction etc. The cooling required to condense the moisture to the desired dewpoint is based on the Thermal Mass to Air/Gas heat-load and the pre-cooler effectiveness.

Our premium series of large capacity thermal mass/fly wheel dryers have the following features:

- Rugged Shell and Tube construction.

- Customized low pressure drop < 0.1 Bar (optional )*

- PLC with 7 inch Touchscreen HMI w/ RS 485 connectivity.

- Turn down capabilities to achieve POWER SAVINGS based on.

- Proprietary Exal developed modes for POWER SAVINGS based on site conditions.

- Selectable dewpoint value to achieve POWER SAVINGS

- Responsive modes for quick ramp up in case of load fluctuation.

- Suction and Discharge Pressure Transmitters.

- Temperature Transmitters for Air/ Gas inlet, Water Inlet and Pressure Dewpoint.

- Temperature, refrigerant pressure and fault log and charts etc.

- Motor Voltage Protection Device

- Low Oil Level Trip

- Condensers with 17 G copper tubes ¾” Dia for easy de-scaling.

RNR / Exal has the lowest committed and delivered pressure drops in the industry. Our systems have been designed for very low-pressure applications such as use with blowers where working pressure is 0.5 Bar(g) and pressure drop is critical.

Our standard series of Small/ large capacity water cooled thermal mass dryers have the following features:

- Rugged Shell and Tube construction.

- Customized low pressure drop < 0.1 Bar (optional )*

- PLC with touchscreen HMI for temperature, fault logging. (optional)

- Air Inlet Temperature, Water Inlet Temperature, Dewpoint displays.

- Motor Voltage Protection Device

- Condensers with 17 G copper tubes ¾” Dia for easy de-scaling.

RNR / Exal has the lowest committed and delivered pressure drops in the industry. Our systems have been designed for very low-pressure applications such as use with blowers where working pressure is 0.5 Bar(g) and pressure drop is critical.

Our standard series of small capacity air cooled thermal mass dryers have the following features:

- Rugged Shell and Tube construction.

- Air Inlet Temperature, Water Inlet Temperature, Dewpoint displays.

- PLC with touchscreen HMI for temperature, refrigerant pressure, fault logging. (optional)

- Large capacity condensers for easy cleaning.

- Fan on/ off Switch