Who we are?

The History of RNR machines / Exal Corporation

We have numerous installations > 30,000 cfm with some single plant installations running into 100,000 CFM. The experience of such large installations is invaluable. The performance of dryers are inter-linked in large common header systems. Closing a valve in one location can result in operational changes in a compressor and/or a dryer or multiple units.

RNR machines today manufactures some of the largest dryers in the world. Our utility wide experience allows us to visualize common issues plaguing large utilities. Our designs are not a simple extrapolation of size. It is a combination of unique theoretical knowledge and in-house propriety simulation which is used along with experience based mechanical and thermal structures to aid machine performance.

What most of our competition gets wrong: is 1000 cfm is “X” then 10,000 cfm is “10X”.

RNR, Exal optimizes its design to get the maximum output at lowest costs. We customize almost every aspect of our machine design.

With knowledge and strength comes commitment. Our systems are committed not just on paper but at site. The result is a confidence which the client can have in us. RNR/ EXAL enjoys almost a 95% client retention rate due to this reason.

Design

Two customers can operate the same Air / Gas Compressor in very different ways. The result on the dryers are also different. While many of the points are redundant, we base our design decisions for dryers ( >1500 SCFM) on the following points, parameters and factors :

RNR Machines

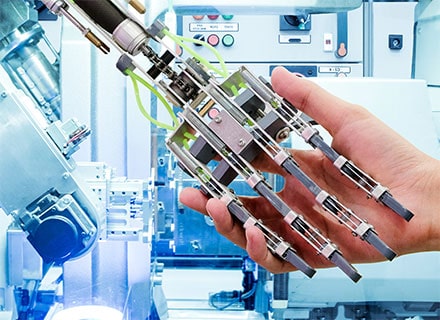

Infrastructure

The plant is divided into 2 sections with a double height 40 Feet Section reserved for assembly of large machines and skids. The second section is two floor are reserved for fabrication, assembly, testing and smaller machinery. Apart from a separate machine shop, there is a separate office + admin + engineering building.